Crystalline PV

- Home

- Benchtop Solutions

- Technobis

- Crystalline PV

Crystallization

Parallel crystallization made visible

Parallel Crystallizer with Particle Viewer

In addition to providing all the benefits of Technobis’s Crystalline SE (Standard Edition), the Crystalline PV (Particle Viewer) enables automatic determination of particle-size distribution and visualization of all crystallization processes, making it perfect for crystallization process development and optimization.

Like other models in the Crystalline range, the PV allows parallel crystallization processes in various modes to meet the needs of a broad range of industries, while its intuitive control and analysis software gives unparalleled access to real-time information on experiments.

- 4 parallel visualization probes make the whole crystallization process visible.

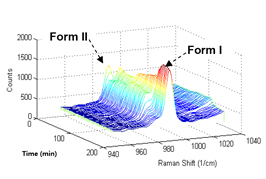

- Modular design allows for customization, e.g. upgrading to Crystalline RR to add Raman spectroscopy.

- 8 independently programmable reactors with stir bar and/or overhead stirring make it possible to study the effect of different solvents or counter-ions in a simple and easy fashion.

- 8 blocks with independently programmable temperature and stirring control with stir bar enable one system to be used simultaneously by several operators.

- 8 independent non-invasive turbidity probes provide real-time turbidity measurements while avoiding cross-contamination.

- ml-scale reaction saves on samples while compact ergonomic design saves valuable laboratory space.

- Range of crystallization techniques (e.g. cooling, evaporation, anti-solvent addition, etc.) supported.

- Real-time observation via a choice of 4 or 8 non-intrusive probes.

- Automatic particle size distribution and shape factor determination.

- Sample illumination: front and back pulsed lighting

- Automatic light intensity control

- Each camera is individually controlled and programmable

- Image analysis software: particle size, distribution and shape

- Precise temperature control (0.1 °C) and fast heating / cooling rate

- ml-scale refluxing capability

- ml-scale slow evaporation with N2 flow

- ml-scale seeding capability

- Automatic light intensity adjustment

- Software for fast report export

- Can mix even the most viscous materials in a controlled fashion

- Feedback control allows response to crystallization events during the temperature cycle

- Process development and optimization

- Finding out what is happening (oiling out, agglomeration) and monitoring habit changes

- Polymorph/solvate/hydrate/co-crystal screening

- Looking for less stable (or meta stable) intermediates

- Controlling growth of certain polymorphs

- Aggregation & potential solvent entrapment

- Solubility curve and MSZW determination

- Single crystal growth