Dispenser Heads

- Home

- Benchtop Solutions

- Microdrop

- Dispenser Heads

A varied range of heads and pipettes for dispensing a wide selection of fluids

Microdrop Dispenser Heads

Microdrop dispenser heads – except for the Nanojet – use the same piezo-driven technology as an inkjet printer for contactless dispensing, generating a micro-fine droplet of liquid at the nozzle tip which departs from the dispenser head at high speed (approximately 2 m/s). Only highly inert materials such as glass, PTFE (polytetrafluorethylene), and PEEK (polyetheretherketone) come into direct contact with the fluid.

Not only is it possible to dispense fluids with a room temperature viscosity up to 20 mPas, but materials such as waxes with a viscosity up to 10,000 mPas are dispensable if their viscosity is reduced by heating to 20 mPas or lower, and some models of dispenser head provide a heating function to accomplish this.

Microdrop dispenser heads have no mechanical moving parts and are therefore free of wear and maintenance.

The microdrop Dispenser Heads MD-K-Series can be driven by the microdrop Driver electronics (MD-E-Series) or in combination with the Autodrop system (AD-E-Series).

- Viscosity range: 0.4-20 mPas depending on fluid used

- Standard inner nozzle diameter: 30μm, 50μm, 70μm

- Droplet volume: 20-180 pl depending on fluid used

- Lifespan: >100 billion cycles

- Viscosity range: 0.4-100 mPas depending on fluid used

- Heating range of nozzle tip: 25-100°C depending on fluid used

- Standard inner nozzle diameter: 30μm, 50μm, 70μm

- Droplet volume: 20-180 pl depending on fluid used

- Lifespan: >100 billion cycles

- Option for heating of hose and storage bin (with MD-H-712 / MD-H-714)

- Viscosity range: 0.4-10,000 mPas depending on fluid used

- Standard inner nozzle diameter: 70μm, 100μm

- Heating range of nozzle tip: 25-80°C depending on fluid used

- Heating range of hose and storage bin: 25-100°C

- Droplet volume: 180-380 pl depending on fluid used

- Lifespan: >100 billion cycles

- Viscosity range: 0.4-10,000 mPas depending on fluid used

- Standard inner nozzle diameter: 70μm, 100μm

- Heating range of nozzle tip: 25-100°C depending on fluid used

- Heating range of hose and storage bin: 25-160°C

- Droplet volume: 180-380 pl depending on fluid used

- Lifespan: >100 billion cycles

- Driver electronics: Autodrop system

- Viscosity range: 0.4-20 mPas depending on fluid used

- Standard inner nozzle diameter: 30μm, 50μm, 70μm

- Droplet volume: 20-180pl

- Storage volume: approx. 37μl

- Variation of dispensed volume: <1%

- Dead volume: approx. 14μl

- Standard drop rate: 1-2,000Hz depending on fluid used

- Fast liquid change

- Transparent body makes it easy to read the filling level at any time

- Viscosity range: 0.4-20 mPas depending on fluid used

- Standard inner nozzle diameter: 30μm, 50μm, 70μm

- Droplet volume: 20-180pl

- Storage volume: approx. 25μl

- Variation of dispensed volume: <1%

- Dead volume: approx. 12μl

- Standard drop rate: 1-2,000Hz depending on fluid used

- Fast liquid change

- Suitable for organic fluids

- High resistance against aggressive fluids

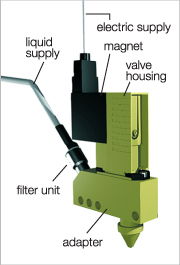

- Permissible liquid viscosity: 0.4-20mPas depending on fluid used

- Nozzle diameter: 50-500µm depending on fluid used

- Permissible particle size: <5µm

- Dispensing volume: 300nl depending on fluid used

- Average speed of emission: approx. 10m/s

- Maximum repetition frequency: 16 Hz

- Minimum opening time: 10 ms

- Maximum opening time at trigger mode: 1.98 s

- Maximum working pressure: 3,500hPa depending on fluid used

- Suitable for watery fluids

- Permissible liquid viscosity: 0.4-50 mPas depending on fluid used

- Nozzle diameter: 50-500µm depending on fluid used

- Permissible particle size: <5µm

- Dispensing volume: 50nl depending on fluid used

- Average speed of emission: approx. 2m/s

- Maximum repetition frequency: 100 Hz

- Minimum opening time: 3 ms

- Maximum opening time at trigger mode: 1.98 s

- Maximum working pressure: 700 / 3,500hPa depending on fluid used

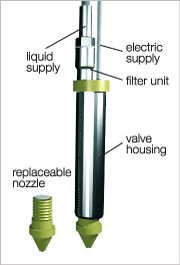

- Viscosity range of up to 2,000 mPas, including all aqueous media, organic solvents, weak acids and alkaline solutions

- Frequency from single pulse to 450Hz

- Valve closed in power-off mode (no dripping or uncontrolled pollution)

- Very long lifespan

- Easily exchangeable nozzles for various applications

- Very good chemical stability

- Intelligent upgraded processor with advanced timing and automatically identification

- Dispensing volume from 8 nl up to 10µl

- Viscosity of dispensed fluids: 1-2,000 mPas

- Dispensing accuracy: <1%